Unveiling the Secrets of Camless Engine Technology

The automotive world stands on the brink of a revolution that could redefine the very heart of internal combustion engines. Camless engine technology, a groundbreaking innovation, promises to transform the way our vehicles perform, consume fuel, and impact the environment. This radical departure from traditional engine design could usher in a new era of efficiency and power, challenging our long-held notions of what's possible under the hood.

The concept of camless engines isn’t new, with research dating back to the 1990s. However, recent advancements in electronic control systems and actuator technology have finally brought this idea within reach of mass production. The potential benefits are staggering: improved fuel efficiency, reduced emissions, enhanced performance, and the ability to tailor engine characteristics on the fly.

Breaking Free from Mechanical Constraints

In conventional engines, the camshaft’s fixed profile dictates valve timing and duration. This one-size-fits-all approach means that engines operate optimally only within a narrow range of conditions. Camless technology shatters these limitations, allowing each valve to be controlled independently and with infinite variability.

This flexibility enables engines to adapt in real-time to changing driving conditions. Imagine an engine that can seamlessly transition from high-performance output for spirited driving to ultra-efficient operation for cruising. The camless system makes this possible by optimizing valve timing and lift for every single combustion cycle.

The Electronic Orchestra: How Camless Engines Operate

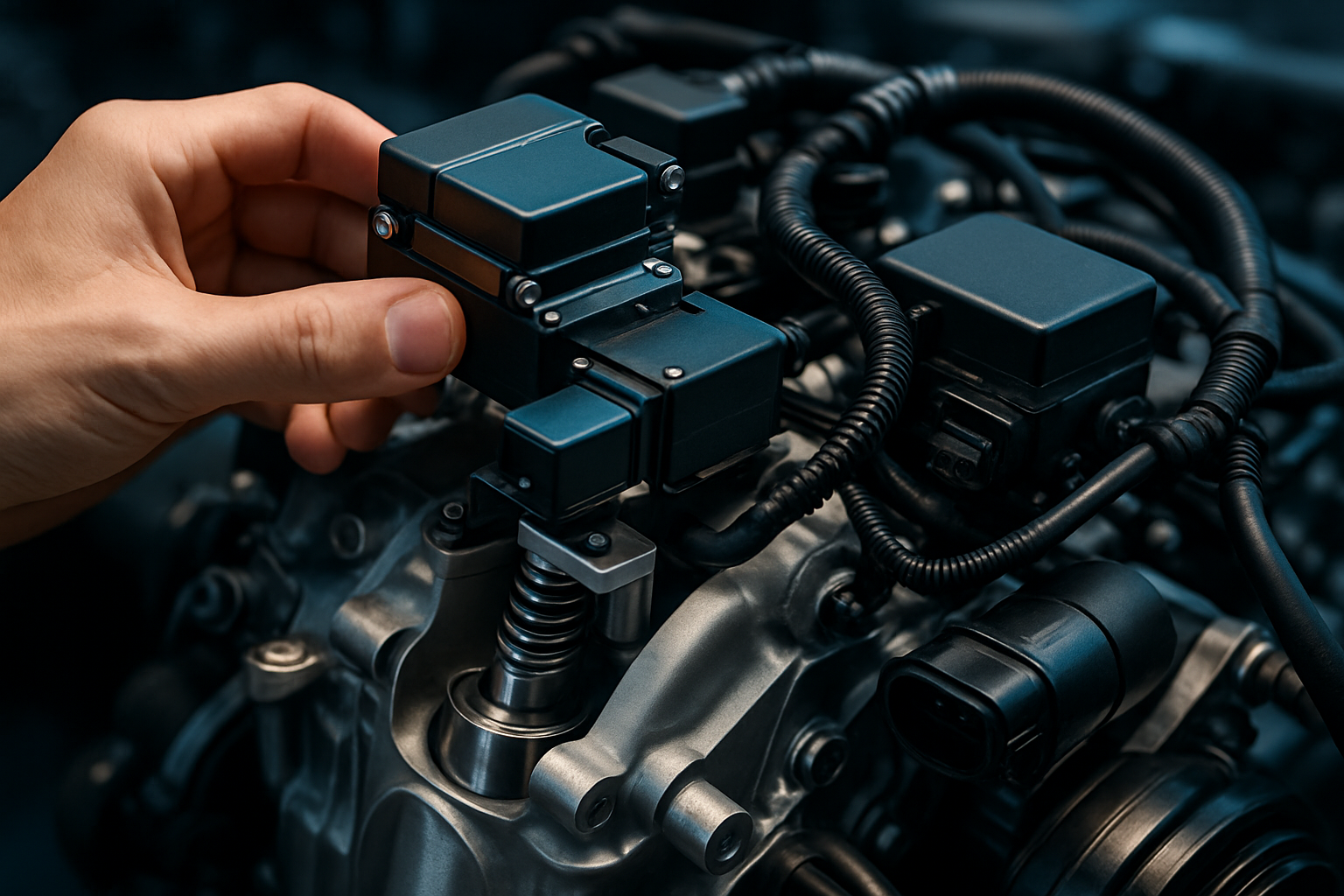

At the heart of camless engine technology are electromagnetic, hydraulic, or pneumatic actuators. These devices replace the traditional system of camshafts, pushrods, and rocker arms. Each valve is controlled by its own actuator, which responds to signals from the engine control unit (ECU).

The ECU acts as the conductor of this mechanical orchestra, coordinating valve movements with millisecond precision. It takes into account a multitude of factors including engine speed, load, temperature, and even driver input to determine the optimal valve timing and duration for each cycle.

This level of control allows for innovative strategies like cylinder deactivation, where individual cylinders can be shut off completely when not needed, further improving fuel efficiency. It also enables more advanced combustion modes, such as homogeneous charge compression ignition (HCCI), which blends the best attributes of gasoline and diesel engines.

Overcoming Hurdles: The Path to Implementation

Despite its promise, camless engine technology faces significant challenges on its path to widespread adoption. One of the primary obstacles is the power demand of the actuators. Early prototypes required substantial electrical energy to operate, potentially negating efficiency gains.

However, recent developments in actuator design and energy recovery systems have made significant strides in addressing this issue. Some designs now incorporate mechanical springs to assist the actuators, reducing their energy consumption. Others explore the use of hydraulic systems that can recapture and reuse energy from the valve closing process.

Another challenge lies in the complexity and cost of the system. The precision required for valve control demands high-quality components and sophisticated software. Manufacturers must balance the potential performance and efficiency gains against the increased production costs.

The Road Ahead: Implications for the Automotive Industry

As camless engine technology matures, its impact on the automotive industry could be profound. Engine designers will have unprecedented freedom to optimize combustion processes, potentially leading to smaller, more efficient engines that deliver the power of larger ones.

The technology also opens up new possibilities for engine sound design. With complete control over valve timing, engineers could potentially craft unique engine notes, adding a new dimension to brand identity and driving experience.

Furthermore, the flexibility of camless engines could extend the lifespan of internal combustion technology in an increasingly electrified automotive landscape. By dramatically improving efficiency and reducing emissions, camless engines could offer a bridge technology as the industry transitions towards full electrification.

As we stand on the cusp of this technological leap, it’s clear that camless engines represent more than just an incremental improvement. They embody a fundamental rethinking of engine design, promising to reshape our expectations of performance, efficiency, and driving dynamics. While challenges remain, the potential rewards make camless engine technology one of the most exciting frontiers in automotive engineering today.