Decoding the Quantum Leap in Industrial Metrology

Precision measurement in industrial settings is undergoing a seismic shift, propelled by quantum technologies. This groundbreaking approach to metrology promises unprecedented accuracy, potentially revolutionizing quality control, product development, and manufacturing processes across diverse sectors. As industries grapple with increasingly complex production demands, quantum metrology emerges as a game-changing solution.

The Foundations of Quantum Metrology

Quantum metrology is rooted in the fundamental principles of quantum mechanics, a branch of physics that describes the behavior of matter and energy at the atomic and subatomic levels. Unlike classical metrology, which relies on macroscopic properties and is limited by statistical uncertainties, quantum metrology exploits quantum states and their unique properties to achieve unprecedented measurement precision.

At the heart of quantum metrology are phenomena such as quantum superposition and entanglement. Superposition allows quantum systems to exist in multiple states simultaneously, while entanglement creates correlations between quantum particles that can be exploited for enhanced measurement sensitivity. These quantum properties enable measurements to approach and even surpass the standard quantum limit, a threshold that was once considered unbreakable in classical physics.

Quantum Sensors: The Next Frontier in Industrial Measurement

Quantum sensors represent the practical application of quantum metrology principles in industrial settings. These advanced devices utilize quantum states to measure physical quantities with extreme accuracy. Unlike traditional sensors, quantum sensors can detect minute changes in magnetic fields, electric fields, gravity, and other physical properties with unparalleled sensitivity.

One prominent example is the quantum magnetometer, which uses nitrogen-vacancy centers in diamond to measure magnetic fields with nanoscale resolution. This technology has found applications in geological surveys, medical imaging, and even in the detection of underground resources. In the manufacturing sector, quantum sensors are being developed to enhance the precision of machine tools, improve the accuracy of coordinate measuring machines, and refine non-destructive testing methods.

Transforming Quality Control with Quantum-Enhanced Precision

The integration of quantum metrology into quality control processes is set to redefine industry standards for precision and reliability. By leveraging quantum sensors and measurement techniques, manufacturers can detect defects and variations at scales previously deemed impossible. This heightened level of scrutiny ensures that products meet increasingly stringent quality requirements, reducing waste and enhancing overall product performance.

In the semiconductor industry, for instance, quantum metrology enables the measurement of atomic-scale features on chips, crucial for the development of next-generation electronics. Similarly, in the automotive sector, quantum-enhanced quality control can lead to the production of more efficient engines and safer vehicles by allowing for tighter tolerances in component manufacturing.

Quantum Metrology in Research and Development

The impact of quantum metrology extends beyond the production line and into the realm of research and development. Scientists and engineers are leveraging quantum measurement techniques to explore new materials, develop advanced technologies, and push the boundaries of what’s possible in product innovation.

In the field of materials science, quantum sensors are being used to study the properties of novel materials at the atomic level, paving the way for the development of stronger, lighter, and more efficient products. The pharmaceutical industry is also benefiting from quantum metrology, with researchers using quantum-enhanced spectroscopy to analyze complex molecular structures, potentially accelerating drug discovery and development processes.

Overcoming Implementation Challenges

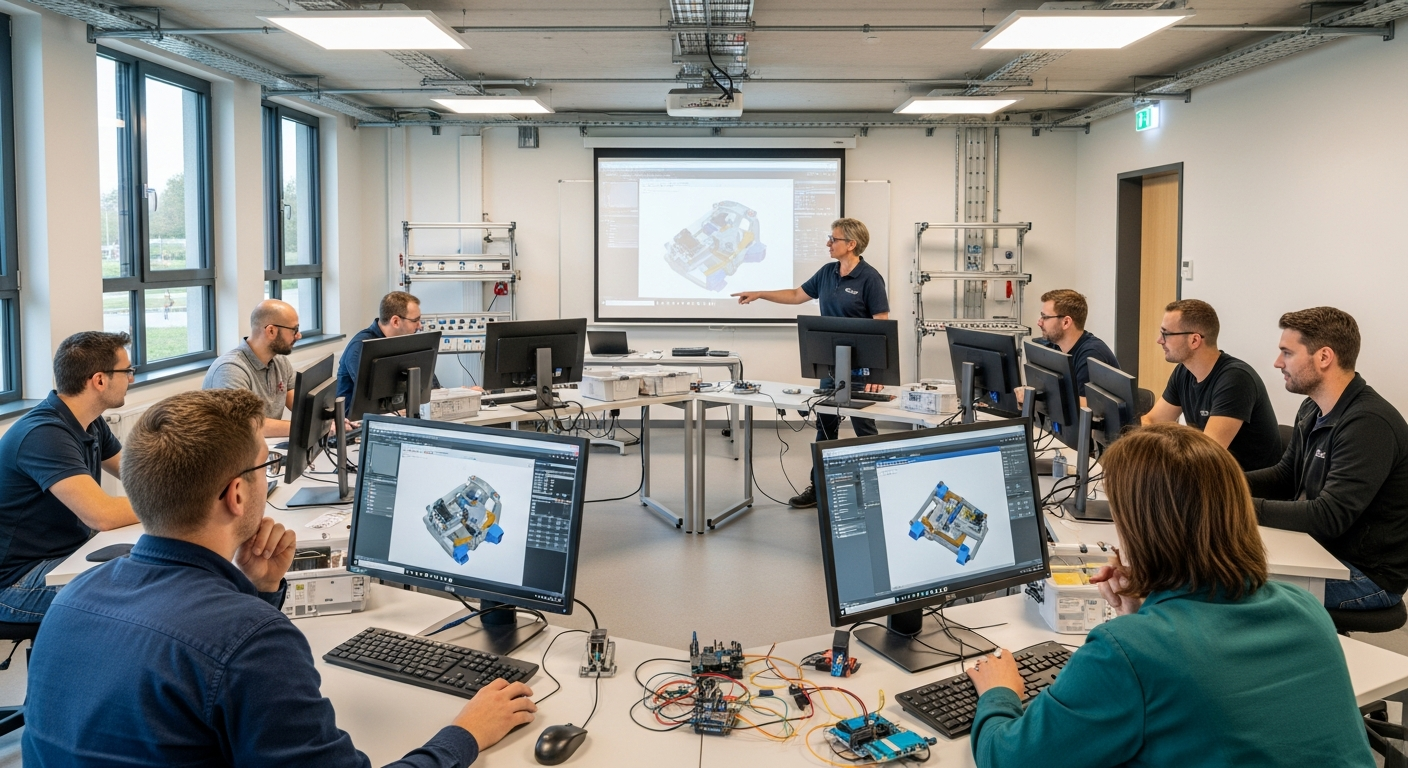

While the potential of quantum metrology is immense, its widespread adoption in industrial settings faces several hurdles. One significant challenge is the need for specialized equipment and controlled environments to maintain quantum states, which can be sensitive to external disturbances. This often requires substantial investment in infrastructure and training.

Additionally, interpreting the data generated by quantum sensors requires advanced data processing and analysis techniques. Companies looking to implement quantum metrology must invest in developing or acquiring the necessary expertise to fully leverage these advanced measurement capabilities.

Despite these challenges, the potential benefits of quantum metrology are driving continued research and development efforts. As the technology matures and becomes more accessible, it is expected to become an integral part of industrial measurement and quality control processes.

Quantum Leap: Practical Insights for Industry Leaders

• Assess your current metrology needs and identify areas where quantum-enhanced precision could provide a competitive advantage.

• Collaborate with research institutions or quantum technology providers to pilot quantum metrology solutions in your operations.

• Invest in training programs to develop in-house expertise in quantum measurement techniques and data analysis.

• Consider forming industry consortia to share the costs and risks associated with implementing quantum metrology infrastructure.

• Stay informed about regulatory developments related to quantum-enhanced measurement standards in your industry.

As quantum metrology continues to evolve, it promises to reshape industrial practices, pushing the boundaries of what’s possible in measurement and quality control. Forward-thinking businesses that embrace this technology early stand to gain a significant competitive advantage, setting new benchmarks for precision and efficiency in their respective industries. The quantum leap in industrial metrology is not just about improving measurements; it’s about unlocking new possibilities for innovation, quality, and productivity in the manufacturing landscape of tomorrow.